What is the raw material used in PP woven bags?

PP woven bags are widely used for packaging various goods due to their durability, flexibility, and cost-effectiveness. These bags are made from a specific type of plastic known as polypropylene (PP). In this article, Vietpak will explore the raw material of PP woven bags and gain a better understanding of the manufacturing process.

1. What is the raw material used in PP woven bags?

Contents

Polypropylene (PP) is the primary raw material used in the production of PP woven bags. It is a thermoplastic polymer that is derived from propylene monomers. PP is widely chosen for manufacturing woven bags due to its unique combination of properties that make it suitable for packaging various goods.

2. The characteristics and advantages of polypropylene

Strength and Durability

Polypropylene offers excellent tensile strength and durability, making it an ideal choice for woven bags. The inherent strength of PP ensures that the bags can withstand heavy loads, rough handling, and transportation without tearing or breaking. This makes them suitable for packaging goods such as agricultural products, chemicals, construction materials, and more.

Lightweight

PP is a lightweight material, contributing to the overall weight reduction of the woven bags. The lightweight nature of PP woven bags makes them easier to handle, stack, and transport. Moreover, it helps in reducing shipping costs, making them a cost-effective packaging solution.

Moisture Resistance

Polypropylene has inherent moisture resistance, making it an excellent choice for packaging goods that require protection against moisture or water damage. PP woven bags can effectively safeguard products such as grains, fertilizers, and other moisture-sensitive items during storage and transportation.

Chemical Resistance

PP exhibits good resistance to a wide range of chemicals, including acids, alkalis, and solvents. This chemical resistance property ensures that the packaged goods remain protected and unaffected by potential chemical interactions during storage or transportation. PP woven bags are commonly used for packaging chemicals, petrochemicals, pharmaceuticals, and other similar products.

UV Resistance

Polypropylene demonstrates good resistance to ultraviolet (UV) radiation. This makes PP woven bags suitable for outdoor applications where prolonged exposure to sunlight is expected. The UV resistance property helps in preserving the bag’s strength, durability, and aesthetic appearance even under direct sunlight, making them suitable for packaging agricultural products, sand, and other outdoor materials.

Low Melting Point

PP has a relatively low melting point compared to other thermoplastics, which facilitates the manufacturing process of PP woven bags. The low melting point allows the polypropylene resin to be easily melted and extruded into long filaments or tapes during the production process. This property makes the manufacturing process efficient and cost-effective.

Polypropylene (PP) is the raw material of choice for manufacturing PP woven shopping bags due to its outstanding properties. Its strength, durability, lightweight nature, moisture resistance, chemical resistance, UV resistance, and low melting point make it an excellent material for packaging various goods. PP woven bags provide a reliable and cost-effective packaging solution for industries such as agriculture, construction, chemical, and more.

Read also: What Did The People Do before Plastic Bags Were Made?

3. The Production Process

The production process of PP woven shopping bags involves several steps, including:

- Polymerization: Propylene monomers undergo a polymerization process, resulting in the formation of polypropylene resin.

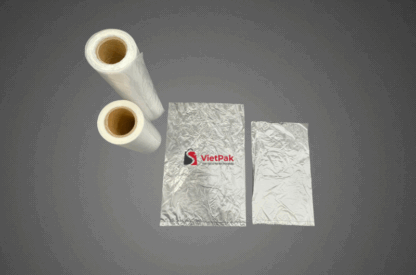

- Extrusion: The polypropylene resin is melted and extruded into long filaments, forming what is known as PP tapes. These tapes are typically flat and have a ribbon-like appearance.

- Weaving: The PP tapes are woven together using specialized machinery to create a fabric-like structure. This woven fabric serves as the primary material for PP woven bags.

- Lamination (optional): In some cases, the woven fabric may undergo lamination to improve its strength, durability, or printing capabilities. Lamination involves coating the fabric with a thin layer of polypropylene or other materials.

- Printing and Bag Making: The woven fabric can be printed with various designs, logos, or labeling information. Afterward, the printed fabric is cut and stitched to form the desired bag shape, such as a sack, tote, or bulk bag.

4. Packaging Applications for Polypropylene

Polypropylene (PP) offers a range of qualities that make it highly advantageous in the packaging industry. These characteristics include:

Non-toxic

PP is non-toxic, making it suitable for various applications, including those in the pharmaceutical and food industries. Its safety ensures the integrity of the packaged products.

Lightweight and Sturdy

Despite its lightweight nature, PP is remarkably sturdy. This makes it an excellent choice for Flexible Intermediate Bulk Containers (FIBCs) that need to hold large quantities of goods, even when they weigh thousands of pounds.

Breathability

Woven polypropylene textiles have a breathable nature, which is crucial for certain applications that require proper air circulation. This characteristic allows for the storage and transportation of goods that need ventilation, such as agricultural products.

Cost-effectiveness

PP is a low-cost material, making it economically accessible for packaging solutions. The affordability of the polymer ensures the widespread availability of polypropylene-based products.

Chemical Resistance

Woven polypropylene bags exhibit resistance to acids, bases, and many chemicals. This property enables their use in various applications, including therapeutic formulations where resistance to specific substances is required.

Printable

Woven polypropylene bags are available in print-ready formats, allowing for branding, labeling, and product information to be added. This feature enhances their versatility and usefulness in marketing and promotional activities.

The unique qualities of polypropylene make it highly suitable for a wide range of packaging applications. Its non-toxic nature, lightweight yet sturdy construction, breathability, cost-effectiveness, chemical resistance, and printability contribute to its popularity in industries such as pharmaceuticals, food, agriculture, and beyond.

Polypropylene (PP) is the primary raw material used in the production of PP woven bags. Its unique properties, such as strength, flexibility, moisture resistance, and low cost, make it a popular choice for packaging various goods. Understanding the raw material and manufacturing process of PP woven shopping bags helps us appreciate the versatility and utility of these packaging solutions in various industries.

LEADING MANUFACTURER

We are a premier plastic bag manufacturer based in Vietnam. Our dedicated team excels in crafting customized packaging solutions to precisely meet the needs of all customers

QUALITY CONTROL

We have a strict quality control system. Our bags are inspected before production, during production, and prior to loading into containers. Our priority is to minimize every defective goods before shipping to our customers

AMAZING SERVICE

Our enthusiastic customer service team always strives to respond to your emails as promptly as possible. We take pride in our ability to consistently deliver high-quality products on time, every time.