What is The Process of Plastic Bag Printing?

Plastic bags are frequently used to package and transport goods, and their aesthetic value is important for branding and marketing. To produce a print that is of high quality and appealing to the eye, plastic bag printing requires several steps. From pre-printing preparation to the finished product, we will examine the nuances of plastic bag printing in this article, emphasizing the significance of sustainable practices in the printing sector.

What are Plastic Bags?

Contents

- What are Plastic Bags?

- Plastic Bag Printing: An Overview

- Plate Making: Creating the Printing Template

- Printing Process: Transferring the Design onto the Bags

- Drying and Finishing: Ensuring Proper Ink Curing

- Quality Control: Ensuring Print Accuracy and Consistency

- Environmental Considerations: Sustainable Practices in Plastic Bag Printing

- Conclusion

- What are Plastic Bags?

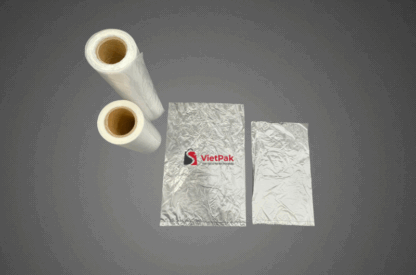

Plastic bags are adaptable and practical packaging solutions made of strong plastic. They offer a useful and dependable method of cargo transportation because they are lightweight and simple to carry. Plastic bags are an affordable option for both consumers and businesses due to their widespread availability.

Moreover, these products are available in a variety of shapes and sizes to suit various requirements, including shopping, storage, and item organization. The water resistance of plastic bags is well known for shielding contents from moisture and ensuring the security of fragile or perishable items. Plastic bags have come under fire for the environment, but people still favor them for everyday use and packaging needs because of how convenient and useful they are.

Plastic Bag Printing: An Overview

To ensure a smooth workflow and successful outcome, thorough pre-printing preparation is necessary before the printing process starts. Choosing the bags’ specifications, such as their size, fabric, and color, is done at this stage. Finding the right printing technique and ink types that support the desired design and printing goals is another important step.

Pre-Printing Preparation

The artwork and design layout are meticulously prepared during the pre-printing phase. Graphic designers with expertise collaborate closely with clients to produce eye-catching designs that successfully communicate the brand message. They take into account things like artwork placement, resolution, and color choice. Proofing and color matching are also done at this stage to make sure the final design adheres to the desired aesthetic standards.

The Arts and Design

Once the design is complete, it is converted to a digital file type that works with the printer. To perfect the design elements and make them print-ready, cutting-edge software tools are used. The design is made to be understandable, accurate, and aesthetically pleasing by graphic designers. To ensure that the printed bags accurately reflect the intended design, this stage also involves color management and proofing.

Plate Making: Creating the Printing Template

The creation of the printing template is involved in the process’ subsequent step, plate making. Onto a printing plate, which is typically made of polyester or polymer, the design is transferred. The printing process uses the plate, which has the desired design’s reverse image, as a template. Although plate-making methods can vary, they typically involve subjecting the plate to UV light or applying chemicals to it in order to create a long-lasting and precise template.

Printing Process: Transferring the Design onto the Bags

Transferring the design to the plastic bags is the key step in the printing process. The printing press is mounted with the prepared plates, and the bags are fed through the device. The bags receive ink from the plates, which imprints the pattern on their surfaces. Depending on the complexity of the design and the desired printing quality, different printing techniques, such as flexographic printing or gravure printing, are used.

Ink Application

To produce vibrant and long-lasting prints, precise ink application is essential during the printing process. The printing press transfers the ink from the plates to the bags after applying it to the plates. Factors like ink viscosity, color consistency, and drying time are carefully taken into account. Modern printing techniques enable precise ink control, guaranteeing accurate design replication and vivid color representation.

Drying and Finishing: Ensuring Proper Ink Curing

The drying and finishing stage starts after the ink has been applied to the bags. To avoid smudging or color transfer during handling and storage, proper ink curing is crucial. Depending on the type of ink and printing equipment used, various drying techniques, such as heat treatment or air drying, may be used. To ensure that the ink cures properly and produces a long-lasting and aesthetically pleasing final product, adequate drying time is allotted.

Quality Control: Ensuring Print Accuracy and Consistency

To maintain print accuracy and consistency, strict quality control procedures are used throughout the printing process. Inspections are carried out at different stages to find any printing flaws, color discrepancies, or registration mistakes. To ensure that the finished product meets the desired standards of quality, adjustments are made as necessary. Each printed bag adheres to the intended design and maintains a high level of aesthetic appeal thanks to meticulous quality control.

Environmental Considerations: Sustainable Practices in Plastic Bag Printing

The printing sector has significantly advanced the adoption of sustainable practices in recent years. To lessen their impact on the environment, many printing companies now give priority to eco-friendly practices. This includes reducing waste generation through effective production processes, implementing programs for recycling used materials, and using water-based inks with lower VOC emissions. By adopting sustainable practices, the sector hopes to support environmental protection and a more sustainable future.

Reference: Understanding Different Printing Techniques for Plastic Bags https://www.plasticsintl.com/blog/understanding-different-printing-techniques-for-plastic-bags

Conclusion

Printing on plastic bags requires thorough preparation, exact execution, and attention to quality assurance. From pre-printing preparation to the finished product, each stage helps to produce visually appealing and robust prints that successfully communicate brand messages.

Also, the printing sector can further reduce its environmental impact and help to create a future that is more environmentally conscious by implementing sustainable practices. The art of printing plastic bags continues to develop through constant innovation and ethical manufacturing, meeting the changing needs of packaging and branding while aiming for a more environmentally friendly and visually appealing customer experience.

LEADING MANUFACTURER

We are a premier plastic bag manufacturer based in Vietnam. Our dedicated team excels in crafting customized packaging solutions to precisely meet the needs of all customers

QUALITY CONTROL

We have a strict quality control system. Our bags are inspected before production, during production, and prior to loading into containers. Our priority is to minimize every defective goods before shipping to our customers

AMAZING SERVICE

Our enthusiastic customer service team always strives to respond to your emails as promptly as possible. We take pride in our ability to consistently deliver high-quality products on time, every time.