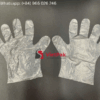

The Applications and Advantages of the plastic gloves

Plastic gloves are an essential component in a variety of settings, serving as a protective barrier to maintain hygiene and safety. These gloves are designed to be worn on the hands to safeguard against contaminants, chemicals, and potential hazards, making them invaluable in both professional and everyday contexts.

What Are Plastic Gloves?

Contents

Plastic gloves are made from various materials, including polyethylene, vinyl, nitrile, and latex. They are generally lightweight, flexible, and provide a protective layer that can help prevent direct contact with harmful substances. The choice of material often depends on the intended use, desired durability, and specific protective needs.

CPE glove

- Material Composition: Plastic gloves are typically made from materials like polyethylene, which is commonly used for light-duty tasks; vinyl, which offers a balance of durability and cost-effectiveness; nitrile, known for its high resistance to chemicals and punctures; and latex, which provides a snug fit and flexibility but may cause allergies in some individuals.

- Design Variations: They come in different sizes, thicknesses, and textures to suit various applications. Some are powdered to make them easier to put on, while others are powder-free to reduce the risk of allergic reactions and contamination.

- Disposable Nature: Most plastic gloves are designed for single-use, ensuring a new, clean layer of protection for each task. This helps to minimize cross-contamination and maintain hygiene.

Applications of plastic gloves

LEADING MANUFACTURER

We are a premier plastic bag manufacturer based in Vietnam. Our dedicated team excels in crafting customized packaging solutions to precisely meet the needs of all customers

QUALITY CONTROL

We have a strict quality control system. Our bags are inspected before production, during production, and prior to loading into containers. Our priority is to minimize every defective goods before shipping to our customers

AMAZING SERVICE

Our enthusiastic customer service team always strives to respond to your emails as promptly as possible. We take pride in our ability to consistently deliver high-quality products on time, every time.