All you need to know about recycled plastic bag factories in Vietnam

Vietnam has been making significant strides in promoting sustainable practices, and one noteworthy industry that has emerged is the production of recycled plastic bags. These factories play a vital role in minimizing plastic waste and reducing environmental impact. In this article, we will explore the key aspects of recycled plastic bag factories in Vietnam.

What is a recycled plastic bag?

Contents

Recycled plastic bags are created through a process known as recycling, which involves collecting and reprocessing plastic waste to produce new products. The recycling process begins with the collection of plastic bags that have been discarded by consumers. These bags are then sorted and cleaned to remove any contaminants.

Once the bags have been cleaned, they undergo a shredding process, where they are transformed into small plastic flakes or pellets. These plastic flakes are then melted down and transformed into a new material that can be used to manufacture recycled plastic bags.

The percentage of recycled material used in the production of these bags can vary. Some bags may contain 30% recycled material, while others can have up to 70% or even 100% recycled content. The exact percentage depends on various factors, including the availability of recycled materials and the manufacturing process used by the bag manufacturer.

The use of recycled plastic bags offers several environmental benefits. Firstly, it helps reduce the demand for virgin plastic, which requires the extraction of fossil fuels and has a significant carbon footprint. By utilizing recycled materials, we can conserve energy and reduce greenhouse gas emissions associated with plastic production.

2 main kinds of recycled material used to make the bag

By utilizing recycled materials, manufacturers are able to create bags that are not only eco-friendly but also of high quality. There are two main types of recycled materials commonly used in bag production: in-house recycled material and post-consumer recycled material.

In-House Recycled Material

One type of recycled material used in bag manufacturing is in-house recycled material. This material is sourced from the factory’s defective goods or the cut-out parts of t-shirt bags. Despite being recycled, in-house materials are clean and of high quality. This is because they originate from within the manufacturing process itself and undergo rigorous quality control measures.

The cut-out parts of virgin bags, which would otherwise go to waste, are also considered in-house recycled materials. These materials can be treated as virgin materials due to their pristine condition. By repurposing these cut-outs, bag manufacturers can significantly reduce their production waste and minimize their environmental footprint.

Post-Consumer Recycled Material

Another significant source of recycled material used in bag production is post-consumer recycled material. This type of material is derived from used plastic goods, including plastic bottles and plastic bags. These items are collected through recycling programs and undergo a thorough sorting and processing system.

The collected plastic goods are cleaned, shredded, and transformed into small pellets or flakes, ready to be incorporated into bag production. By utilizing post-consumer recycled material, bag manufacturers contribute to the reduction of plastic waste in landfills and the conservation of natural resources. Furthermore, this practice promotes a circular economy by reintroducing recycled materials back into the manufacturing process.

The utilization of recycled materials in bag manufacturing has become a vital aspect of sustainable production practices. In-house recycled materials, sourced from the factory’s defective goods and cut-out parts of virgin bags, offer a clean and high-quality alternative to virgin materials. On the other hand, post-consumer recycled materials derived from used plastic goods help reduce plastic waste and conserve resources.

By incorporating these two main types of recycled materials, bag manufacturers demonstrate their commitment to environmental responsibility. Through their efforts, they not only contribute to a greener future but also provide consumers with eco-friendly and durable bags. It is evident that the use of recycled materials in bag production is a positive step towards a more sustainable and environmentally conscious industry.

How is a recycled material made?

Recycling plays a crucial role in reducing waste and preserving our environment. Through the recycling process, various materials can be transformed into new products, reducing the need for extracting raw resources.

Collection and Sorting

The first step in recycling is the collection and sorting of materials. Recycling centers and waste management facilities receive recyclable items from households, businesses, and public places. These materials are then sorted based on their type, such as paper, plastic, glass, or metal, to ensure efficient processing.

Cleaning and Preparing

Once the materials are sorted, they undergo a cleaning and preparation stage. Contaminants like dirt, food residue, or labels need to be removed. In this stage, the recyclables are thoroughly cleaned and inspected for quality assurance. The cleaned materials are then ready for further processing.

Shredding and Pulping

Many recyclable materials, such as paper and cardboard, go through a shredding process. Shredding breaks them down into small pieces, increasing their surface area and making them easier to handle in subsequent steps. For paper, the shredded pieces are mixed with water to create a pulp, while metals, plastics, and glass may be crushed or melted, depending on their composition.

Filtering and Separation

In the next phase, the pulp or crushed materials undergo filtering and separation processes. Filters help remove impurities from the pulp, such as ink particles in the case of paper recycling. Additionally, magnets or eddy currents can be used to separate magnetic metals like steel or aluminum from non-magnetic materials. Optical sorting machines are employed to separate different types of plastics based on their resin identification codes.

Reforming and Manufacturing

Once the materials are sorted and separated, they are ready to be transformed into new products. The reformation and manufacturing processes depend on the specific material being recycled. For example, paper pulp can be used to create new paper products, plastics can be melted and molded into new plastic items, and metals can be melted and shaped into new metal objects.

Quality Control

Throughout the recycling process, quality control is crucial to ensure that the resulting recycled materials meet industry standards. The recycled products undergo rigorous testing to confirm their durability, strength, and safety. Quality control measures help maintain the integrity of the recycling loop and guarantee the viability of using recycled materials in various applications.

Read also: The Price of Recycled T-shirt Plastic Bag

What are the strengths of recycled plastic bag factories in Vietnam?

Vietnam, known for its manufacturing capabilities, has witnessed the rise of recycled plastic bag factories. These factories play a vital role in mitigating plastic pollution and promoting sustainability.

Access to Raw Materials

One of the key strengths of recycled plastic bag factories in Vietnam is their access to abundant sources of raw materials. Vietnam is a major producer and consumer of plastic bags, which results in a significant amount of plastic waste. This waste stream serves as a valuable resource for the factories, enabling them to obtain a consistent supply of recyclable plastic materials.

Advanced Recycling Technologies

Recycled plastic bag factories in Vietnam have invested in advanced recycling technologies. These technologies allow for efficient and effective processing of plastic waste. Processes such as shredding, washing, and extrusion are employed to transform the collected plastic into high-quality recycled pellets or flakes. These recycled materials serve as the foundation for producing new plastic bags.

Integration with Supply Chains

Vietnam’s recycled plastic bag factories have established strong connections with local and international supply chains. They collaborate with various stakeholders, including waste management companies, recyclers, and retailers, to ensure a seamless flow of materials and products. This integration facilitates the efficient collection of plastic waste, boosts the availability of recycled materials, and enhances the distribution of recycled plastic bags.

Cost-Effectiveness

Recycled plastic bag factories in Vietnam offer cost-effective solutions. The abundance of raw materials, coupled with streamlined manufacturing processes, allows for competitive pricing. This affordability encourages businesses and consumers to opt for recycled plastic bags, creating a market demand that supports the sustainability of these factories.

Environmental Benefits

Vietnam’s recycled plastic bag factories provide significant environmental benefits. By utilizing plastic waste as a raw material, these factories divert plastic from landfills and oceans, reducing the overall environmental impact. The production of recycled plastic bags requires fewer resources, such as energy and water, compared to manufacturing new plastic bags from virgin materials. This conservation of resources contributes to a more sustainable and eco-friendly production process.

Where to buy recycled plastic bag bulk?

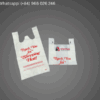

Finding alternatives to single-use plastic bags has become a priority for many individuals and businesses. One popular option is to purchase recycled plastic bags in bulk, which not only helps reduce the demand for new plastic but also supports the recycling industry. If you’re looking for a reliable source to buy recycled plastic bags in bulk, Vietpak is an excellent choice.

Vietpak – recycled plastic bag factories in Vietnam is a renowned supplier of eco-friendly packaging solutions based in Vietnam. The company specializes in producing high-quality recycled plastic bags that meet international standards. They have built a strong reputation for Vietpak’s commitment to sustainability, product innovation, and customer satisfaction.

One of the primary advantages of choosing Vietpak as your supplier for recycled plastic bags in bulk is Vietpak’s extensive range of products. Whether you need standard-sized bags, custom designs, or specialized features like biodegradable additives, Vietpak can cater to your specific requirements. Vietpak’s diverse selection ensures that you will find the right type of bag to suit your business needs.

Vietpak’s commitment to customer satisfaction is evident in Vietpak’s excellent customer service. They have a team of knowledgeable and friendly professionals who are ready to assist you throughout the ordering process. Whether you have questions about Vietpak products, need guidance on selecting the right bags, or require assistance with customization, Vietpak’s dedicated staff will ensure that your experience is seamless and enjoyable.

LEADING MANUFACTURER

We are a premier plastic bag manufacturer based in Vietnam. Our dedicated team excels in crafting customized packaging solutions to precisely meet the needs of all customers

QUALITY CONTROL

We have a strict quality control system. Our bags are inspected before production, during production, and prior to loading into containers. Our priority is to minimize every defective goods before shipping to our customers

AMAZING SERVICE

Our enthusiastic customer service team always strives to respond to your emails as promptly as possible. We take pride in our ability to consistently deliver high-quality products on time, every time.