PP Non Woven Sack Manufacturing Process

PP Non Woven Sacks are produced and printed according to customer’s demands and requirements. End users use different color combinations and designs for printing these sacks to convey messages, characteristics, quantity, and quality-related details, as well as handling instructions. In specific applications such as filling hygroscopic materials like chemicals, fertilizers, and food products, these nonwoven sacks are also laminated.

Vietpak’s PP Non Woven sack manufacturing process exclusively utilizes pure virgin polypropylene resins. Each bag undergoes quality checks before being packed and shipped.

Comprehensive quality management systems are strictly followed at every stage of the manufacturing process, including tape extrusion, extrusion lamination, gravure printing, bag formation, bag sewing, quality testing, and customer shipping. We strive to meet the latest requirements for non woven polypropylene sacks to ensure our customers receive the highest quality international products.

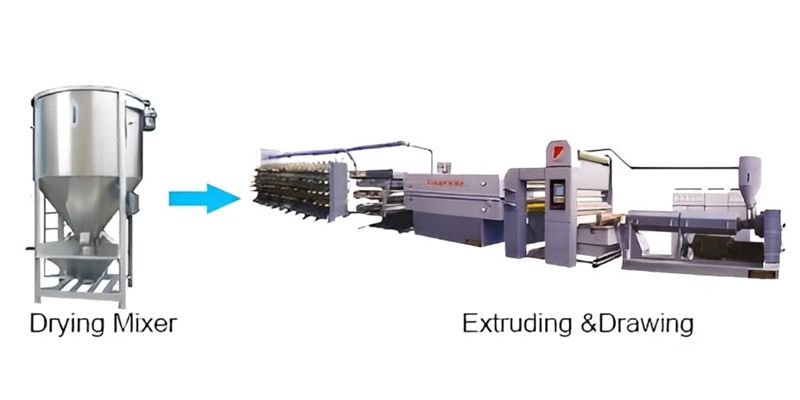

Extrusion & Winding

Contents

State-of-the-art technology is incorporated into high-speed extrusion, double-stage draw, tape stretching, and winding lines to produce PP/HDPE tapes. These lines are designed to meet the highest performance and quality requirements, maximizing efficiency and flexibility while minimizing raw material and energy usage.

The process of PP Non Woven sack manufacturing process begins with the mixing of raw materials, starting with PP pellets and other additives. The raw materials are then extruded into yarn, with the PP resin heated and combined with CaCo3 and pigment. The melted resin is extruded as a flat film, which is then slit into tape yarn by a slitting unit and subsequently stretched and annealed. The heat-oriented tape yarn is then wound onto a bobbin by a take-up winder.

To obtain the Raffia Tapes of PP, the raw material (PP & Filler) in granule form is fed into a Raffia Tape Manufacturing Plant. The raw material mix is prepared in a tray adjacent to the feed hopper and is then vacuum-sucked into the hopper. The raw material mix is then transported to the extruder of the plant, where controlled external heat is applied to melt the material in the barrel.

The molten mass is forced through a die head into a cooling tank, forming a sheet/film. The cooled and solidified sheet/film is passed through knives to obtain Raffia Tapes with a higher denier (a unit for measuring yarn fineness). High-density polyethylene (HDPE) or polypropylene (PP) granules are initially converted into 2.5 mm wide tapes through the extrusion process. The Raffia Tapes received from the plant are then stretched, annealed, and wound on cheese pipes with the help of sets of winders.

PP Non Woven sack manufacturing process – Bag Conversion

High-speed bag conversion lines manufacture bottom folded and sewn nonwoven sacks using rolls of tubular nonwoven PP/HDPE fabric. These modern machines are well-suited for traditional bag applications. These are specifically designed to cross-cut the tubular fabric, fold the bottom, sew the bags, and stack them.

The incorporation of state-of-the-art automated functions ensures consistent quality in the cutting and sewing process. These lines can be referred to as automated conventional bag production machines.

Multi Filament Yarn

The multi-filament spin-draw-wind line provides a highly flexible concept of compact melt-spinning lines. Each line is designed to meet strategic and operational requirements at an optimal cost.

These lines are well-suited for producing high tenacity, medium to heavy denier yarn in small batches, catering to specific needs or niche applications. They also possess the capability to adapt to dynamic market demands quickly.

Read also: How are non woven polypropylene bags made?

PP Non Woven sack manufacturing process – Testing & Packing

All necessary laboratory equipment is utilized to conduct quality checks at every stage of production, ensuring impeccable quality for customers.

The bags undergo inspection, sorting, and stacking to ensure proper customer shipping. To facilitate systematic and cost-efficient storage and transportation, hydraulic pallets and bale presses compress and pack the finished bags for protection.

The rolls of non woven cloth are transported to the finishing and stitching section of the unit. The cloth is cut into the desired sizes and then printed. After printing, the cut pieces are sent for stitching. Before stitching, a valve is incorporated in one corner of each cut piece according to customer specifications.

Non Woven sacks that pass the quality control tests are bundled in quantities of 500 or 1000 and compressed using a baling press. The pressed non woven sacks are then wrapped, bundled, packed, and dispatched.

Quality control checks are conducted at each step to minimize rejections. Parameters such as weight, denier, bursting strength, and other relevant factors are strictly adhered to.

LEADING MANUFACTURER

We are a premier plastic bag manufacturer based in Vietnam. Our dedicated team excels in crafting customized packaging solutions to precisely meet the needs of all customers

QUALITY CONTROL

We have a strict quality control system. Our bags are inspected before production, during production, and prior to loading into containers. Our priority is to minimize every defective goods before shipping to our customers

AMAZING SERVICE

Our enthusiastic customer service team always strives to respond to your emails as promptly as possible. We take pride in our ability to consistently deliver high-quality products on time, every time.