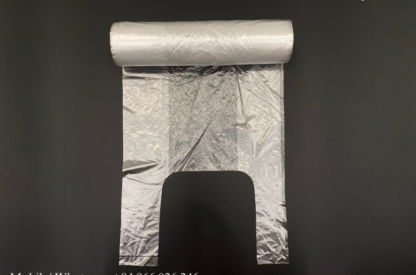

Stretch Film – Durable & Cost-Effective Packaging Solution

Stretch film is a vital tool for safeguarding goods during transport and storage, offering unmatched stability and protection for pallets of all shapes and sizes. This versatile material ensures products remain secure, reducing damage and enhancing efficiency in logistics. In this article, we explore the benefits, types, and applications of this essential packaging solution, highlighting its role in modern supply chains.

Ensuring Pallet Stability with High-Performance Solutions

Contents

The primary function of stretch film is to provide robust pallet stability, ensuring goods remain intact during handling and transportation. Advanced formulations of this material cater to diverse load types, from lightweight packages to heavy industrial items. Manufacturers design these films to withstand varying weights and shapes, delivering reliable performance across industries.

Optimizing Wrapping Processes

High-performance stretch film enhances wrapping efficiency by minimizing downtime and ensuring consistent application. Specialized films are compatible with automated wrapping machines, streamlining operations and reducing labor costs. By selecting the right film, businesses can achieve compact, secure pallets with minimal material usage, contributing to cost savings and operational uptime.

Reducing Costs and Material Usage

Cost efficiency is a key advantage of modern stretch film solutions. Engineered to deliver maximum strength with minimal thickness, these films reduce the amount of material needed per pallet. This not only lowers expenses but also supports sustainability by decreasing waste. Technical expertise ensures the film is applied optimally, further driving down costs without compromising quality.

Enhancing Load Security

The elasticity and strength of stretch film make it ideal for securing loads against shifting or collapsing during transit. By tightly binding goods to pallets, it prevents damage, protects against environmental factors, and reduces the risk of workplace injuries caused by unstable loads. This reliability is critical for maintaining product integrity and customer satisfaction.

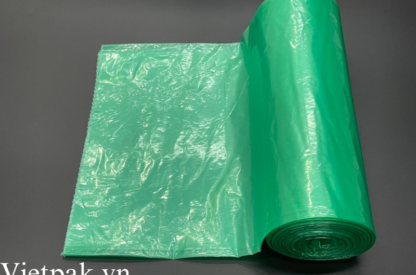

Exploring LDPE Stretch Film – A Versatile Packaging Material

Low-Density Polyethylene (LDPE) stretch film is a widely used packaging material known for its flexibility, durability, and affordability. Made from high-quality LDPE resin, this film offers excellent elasticity and strength, making it suitable for a range of applications. Its ability to conform to product shapes ensures a snug fit, providing superior protection during storage and transit.

Key Features of LDPE Stretch Film

LDPE stretch film is crafted from linear low-density polyethylene, offering a balance of flexibility and toughness. Available in various thicknesses, widths, and lengths, it can be tailored to specific packaging needs. Its transparent nature allows for easy product identification, while its single-layer lamination adds protection against dust, moisture, and scratches. The film’s softness ensures it wraps products without causing surface damage.

Benefits of Using LDPE Stretch Film

The advantages of LDPE stretch film extend beyond its affordability. Its puncture resistance safeguards goods from sharp edges and impacts, ensuring they reach their destination in pristine condition. The film’s clarity eliminates the need for additional labeling, streamlining inventory management. Additionally, its versatility allows it to be used manually or with automated dispensers, enhancing operational efficiency.

Applications Across Industries

LDPE stretch film is employed in numerous sectors due to its adaptability. In pallet wrapping, it secures goods for safe transport, preventing movement and damage. It is also used to wrap individual boxes, protect furniture during moves, and shield surfaces during construction or renovations. Its ability to adhere to itself without adhesives makes it a convenient and reusable option for various packaging tasks.

Sustainable and Innovative Stretch Film Solutions

Sustainability is a growing priority in packaging, and stretch film manufacturers are responding with eco-friendly innovations. Films incorporating recycled content, such as Post-Consumer Recycled (PCR) materials, reduce environmental impact without sacrificing performance. These advancements align with global efforts to minimize waste and promote a circular economy.

Incorporating Recycled Content

Modern stretch film options include versions with up to 30% or even 51% PCR content. By integrating high-quality recycled materials, these films lower the carbon footprint and contribute to waste reduction. Businesses adopting these solutions can meet sustainability goals while maintaining the strength and reliability needed for secure packaging.

Supporting a Circular Economy

The use of recycled stretch film helps close the material loop, reducing reliance on virgin plastics. Manufacturers are investing in technologies to improve the quality of recycled films, ensuring they meet the same performance standards as traditional options. This shift supports long-term environmental sustainability and appeals to eco-conscious consumers and businesses.

Partnering for Optimal Performance

Collaboration with experienced manufacturers is key to maximizing the benefits of stretch film. Technical experts provide guidance on selecting the right film, optimizing wrapping processes, and achieving cost savings. By leveraging in-depth knowledge of pallet loads and wrapping equipment, businesses can enhance efficiency, reduce material consumption, and ensure reliable load stability.

Frequently Asked Questions About LDPE Stretch Film

Q: How strong is LDPE stretch film?

A: LDPE stretch film is crafted from premium-grade low-density polyethylene, offering exceptional toughness and resilience for reliable performance.

Q: Can LDPE stretch film be tailored to specific needs?

A: Absolutely, this stretch film can be customized to conform precisely to the contours of various products, ensuring a snug fit.

Q: Is LDPE stretch film gentle on surfaces?

A: Yes, its pliable and soft texture allows it to wrap items securely without scratching or damaging delicate surfaces.

Q: Does LDPE stretch film shield against environmental elements?

A: Indeed, its single-layer design forms a protective barrier, safeguarding products from dust, moisture, and minor abrasions.

Q: Is LDPE stretch film clear for visibility?

A: Yes, its transparent nature ensures that wrapped items remain visible, facilitating easy product identification and inventory tracking.

Conclusion

Stretch film remains an indispensable tool in the packaging industry, offering a blend of durability, cost-efficiency, and sustainability. Its ability to secure goods, reduce waste, and adapt to various applications makes it a cornerstone of modern logistics. Businesses that invest in high-quality films and expert support can achieve significant operational and environmental benefits, ensuring their products are protected and their supply chains are optimized.

LEADING MANUFACTURER

We are a premier plastic bag manufacturer based in Vietnam. Our dedicated team excels in crafting customized packaging solutions to precisely meet the needs of all customers

QUALITY CONTROL

We have a strict quality control system. Our bags are inspected before production, during production, and prior to loading into containers. Our priority is to minimize every defective goods before shipping to our customers

AMAZING SERVICE

Our enthusiastic customer service team always strives to respond to your emails as promptly as possible. We take pride in our ability to consistently deliver high-quality products on time, every time.