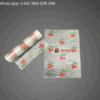

100% Virgin Freezer Food Storage Bags Made in Vietnam

A freezer food storage bag is a specialized type of plastic bag designed specifically for storing food in the freezer. These bags are made from materials that are resistant to low temperatures and are constructed to protect food from freezer burn, moisture loss, and contamination. Freezer food storage bags typically come in various sizes and styles to accommodate different types of food items and storage needs.

Freezer plastic bag on roll

Key features of freezer food storage bag

Contents

Thickness

The thickness of freezer food storage bags can vary depending on the brand and specific product. However, in general, freezer bags are typically thicker than regular plastic bags to provide better protection against freezer burn and to withstand the low temperatures of the freezer environment.

Freezer bags usually range in thickness from around 0.7 mils (0.018 mm) to 3 mils (0.076 mm). Thicker freezer bags, such as those around 2 to 3 mils thick, offer increased durability and are less prone to tearing or puncturing, making them suitable for storing heavier or sharper food items. On the other hand, thinner freezer bags, such as those around 0.7 to 1 mil thick, are more flexible and may be better suited for lighter items or for situations where space-saving is a priority.

When selecting freezer food storage bags, it’s essential to consider the intended use and the type of food items you plan to store. Thicker bags are generally preferable for long-term storage of items like meats, soups, or casseroles, while thinner bags may be sufficient for items like fruits, vegetables, or leftovers that will be consumed relatively quickly.

Material

Freezer storage bags are typically made from plastic materials that are specifically designed to withstand low temperatures and protect food from freezer burn and contamination. The most common materials used for freezer storage bags are:

High-Density Polyethylene (HDPE): HDPE is a durable and versatile type of plastic that is commonly used for freezer bags. It has excellent resistance to low temperatures and is relatively rigid, providing good protection for frozen food items. HDPE is also known for its strength and resistance to chemicals, making it a suitable choice for food storage applications.

Low-Density Polyethylene (LDPE): LDPE is another type of plastic that is commonly used for freezer storage bags. It is more flexible and has better clarity compared to HDPE, making LDPE bags easier to handle and allowing users to see the contents inside. LDPE is also resistant to low temperatures and provides adequate protection for frozen foods.

Both HDPE and LDPE are approved by regulatory agencies for food contact and are considered safe for storing food. These materials are free from harmful chemicals like BPA (bisphenol A) and phthalates, ensuring that they do not leach into the food stored in the bags.

In addition to HDPE and LDPE, some freezer storage bags may also incorporate other materials or additives to enhance their performance. For example, freezer bags may include a special coating or film that provides an extra barrier against moisture and air, further protecting the food from freezer burn.

When purchasing freezer storage bags, it’s essential to choose products that are specifically labeled as “freezer-safe” or “designed for freezer use” to ensure that they are suitable for storing food at low temperatures. Always follow manufacturer instructions for proper usage and storage to maximize the effectiveness of freezer storage bags in preserving the quality and freshness of your food.

Size options

Freezer plastic bags typically come in a variety of size options to accommodate different storage needs and quantities of food items. Common size options for freezer plastic bags include:

Snack Size (Small): These are typically smaller bags, suitable for storing small portions of snacks, sliced fruits, or single servings of leftovers. Snack-sized freezer bags are convenient for portion control and for packing snacks for on-the-go

Quart Size: Quart-sized freezer bags are a popular choice for storing leftovers, individual portions of soups or stews, and smaller cuts of meat or poultry. They offer enough capacity to store a moderate amount of food while still being compact and space-saving.

Gallon Size: Gallon-sized freezer bags are larger and offer more storage space than quart-sized bags. They are suitable for storing larger quantities of food, such as bulk purchases of meat, vegetables, or prepared meals. Gallon-sized bags are ideal for families or individuals who need to store larger portions of food.

2-Gallon Size: These are even larger freezer bags designed to accommodate extra-large quantities of food. They are suitable for storing large cuts of meat, batches of homemade soups or sauces, or bulky items like whole chickens or roasts.

Jumbo Size: Jumbo freezer bags are the largest size option available and are designed for storing very large or bulky items. They are ideal for freezing large quantities of fruits or vegetables, bulk purchases of meat or poultry, or for storing items in odd shapes or sizes.

In addition to these standard size options, freezer plastic bags may also come in specialty sizes or shapes to accommodate specific storage needs. Some brands offer extra-wide bags, extra-long bags, or bags with expandable bottoms to provide additional storage space or accommodate larger items.

When selecting the size of freezer plastic bags, consider factors such as the amount of food you need to store, the available freezer space, and how you plan to use the bags. It’s often helpful to have a variety of sizes on hand to accommodate different types of food items and storage requirements.

LEADING MANUFACTURER

We are a premier plastic bag manufacturer based in Vietnam. Our dedicated team excels in crafting customized packaging solutions to precisely meet the needs of all customers

QUALITY CONTROL

We have a strict quality control system. Our bags are inspected before production, during production, and prior to loading into containers. Our priority is to minimize every defective goods before shipping to our customers

AMAZING SERVICE

Our enthusiastic customer service team always strives to respond to your emails as promptly as possible. We take pride in our ability to consistently deliver high-quality products on time, every time.